The Ultimate Guide to Barcode Printers

In today's fast-paced business environment, the efficiency and speed of operations are paramount. One essential tool that has revolutionized the way businesses handle inventory, shipping, and sales is the barcode printer. This article delves deep into the world of barcode printers, covering their importance, functionalities, types available, and how they can drive efficiency in your business.

Understanding Barcode Printers

A barcode printer is a specialized printing device designed to produce barcode labels and tags. These printers play a vital role in various applications, ranging from retail to manufacturing and logistics. By employing different printing technologies, these devices help businesses streamline their operations, enhance accuracy, and reduce errors.

Why Use a Barcode Printer?

In any business, accuracy is crucial. Here are several reasons why investing in a barcode printer is beneficial:

- Improved Accuracy: By automating data entry, barcode printers help eliminate human errors.

- Increased Speed: Barcodes can be scanned quickly, facilitating rapid checkout and inventory tracking.

- Cost-Effective: Reducing errors and improving efficiency can lead to significant cost savings over time.

- Enhanced Tracking: Barcodes allow for precise tracking of products throughout the supply chain.

- Better Inventory Management: By using a barcode printer, businesses can maintain accurate inventory records, leading to improved stock management.

Types of Barcode Printers

Understanding the types of barcode printers available can help you choose the right one for your business needs. Here are the primary categories:

1. Thermal Transfer Printers

Thermal transfer printers use heat to transfer ink from a ribbon onto the label material. This type of printer is known for producing high-quality, durable prints suitable for various environments.

- Ideal for long-lasting labels

- Works well with different materials, including synthetic substrates

- Commonly used in industrial applications

2. Direct Thermal Printers

Unlike thermal transfer printers, direct thermal printers do not require ink or ribbons. Instead, they use heat-sensitive paper that darkens when heated. This makes them suitable for short-term labeling and applications where longevity is not a concern.

- Lower operational costs since no ribbons are needed

- Ideal for shipping labels, receipts, and temporary labels

- Risk of fading if exposed to heat or light

3. Inkjet Printers

Inkjet barcode printers provide high-quality color printing, making them suitable for products that require graphics alongside barcodes. They are versatile but generally slower than thermal printers.

- Produces vibrant colors and detailed images

- Suitable for marketing labels and packaging

- Higher running costs due to ink consumption

4. Laser Printers

Laser barcode printers use a laser to produce high-quality prints at a fast speed. They are ideal for high-volume printing and can produce barcodes with a high level of detail.

- Fast printing speeds, ideal for high-demand environments

- High-quality prints that are resistant to smudging

- Higher upfront costs, but lower per-page costs

Applications of Barcode Printers

Barcode printers are applicable in many sectors, enhancing operational efficiency and accuracy. Here are some major applications:

1. Retail

In retail settings, barcode printers are crucial for producing price tags, shelf labels, and inventory management labels. They enable quick scanning at checkout, reducing wait times and improving customer satisfaction.

2. Manufacturing

In the manufacturing industry, barcode printers are used to label products, components, and pallets. This helps track items throughout the production process, facilitating better inventory management.

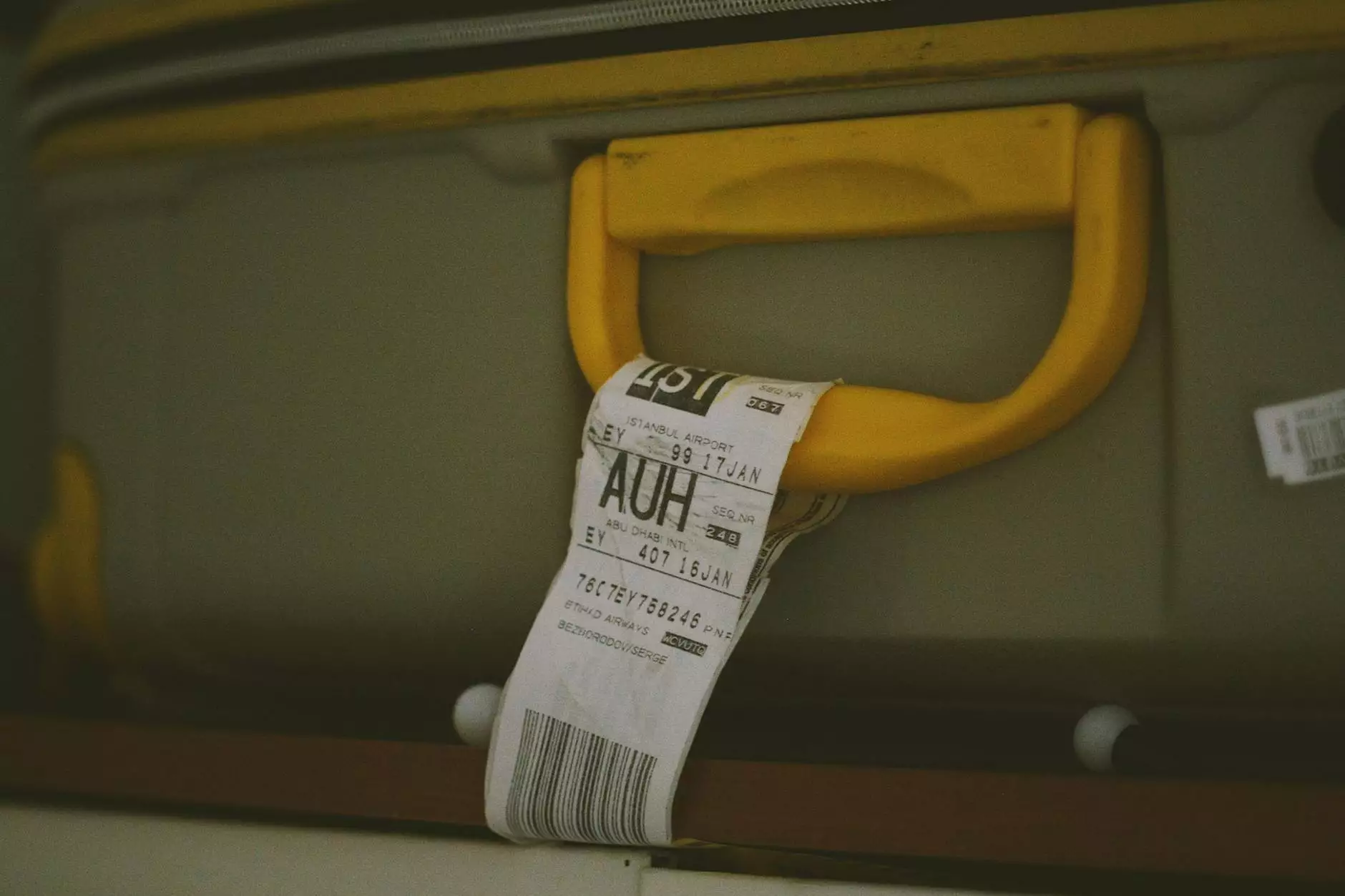

3. Logistics and Shipping

Barcode printers streamline logistics by creating shipping labels and tracking labels. These labels allow for efficient product tracking throughout the distribution chain, ensuring timely deliveries.

4. Healthcare

In healthcare, barcode labels are crucial for patient identification, medication tracking, and asset management. This minimizes errors, enhances patient safety, and improves overall operational efficiency.

Choosing the Right Barcode Printer for Your Business

Selecting the right barcode printer is vital to ensuring that your business operates smoothly. Here are several factors to consider:

1. Print Volume

Consider how many labels you will need to print per day. If your print volume is high, a thermal transfer or laser printer may be a better choice due to their speed and efficiency.

2. Type of Labels

Different printing technologies produce different types of prints. Determine if you require durable labels for long-term use or temporary labels, and choose accordingly.

3. Color vs. Monochrome

If you need to print graphics or use different colors, consider an inkjet printer. If high-speed, high-volume monochrome printing is more appropriate, a thermal or laser printer would be a better fit.

4. Connectivity Options

Assess the connectivity options you need. Many modern printers offer USB, Ethernet, and wireless options, making it easier to integrate them into your existing systems.

5. Budget

Determine your budget not just for the printer itself but also for consumables like ribbons, ink, and maintenance costs. Balancing cost with functionality is key.

Benefits of Incorporating Barcode Printing Technology

Implementing a barcode printer in your business brings numerous advantages...

1. Operational Efficiency

Barcode printing technology increases the overall efficiency of your operations by streamlining processes. Tasks that once took minutes can be completed in seconds.

2. Enhanced Data Accuracy

By eliminating manual data entry through barcode scanning, the chances of errors decrease significantly, leading to more reliable data.

3. Real-Time Data Tracking

The integration of barcode printing allows businesses to track products in real-time, ensuring inventory levels are always accurate and up-to-date.